Radar PCB |

Military High Frequency PCB Rapid Prototype,24 hours |

|

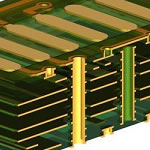

| HDI PCB | HDI PCB fast prototyping ! | |

| Rapid Prototype | blind via PCB Rapid Prototype China, |

HDI PCB |

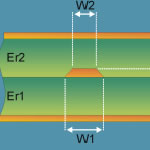

rogers4003C Rogers4350B PCB fabrication |

|

| Rogers4350B | Rogers4350B PCB manufacturer quick turn | |

| Rogers4003C | Rogers4003C blind via PCB manufacturing |

RF PCB |

High Frequency RF PCBA, rapid prototype |

|

| flex pcb | contract electronic manufacturing china, volume and prototype | |

| BGA reball | PCB repair BGA reball rework PCB manufacturing |

For furhter information, please feel free to contact us, www.pcbsino.com