Radio base station Rogers PCB aplication

China PCB Manufacturing, Shenzhen PCB Manufacturer, Making Circuit boards

PCB Contract manufacturer, PCB Fabrication, Turnkey assembly services

Buy Print circuit board, customer: /USA/UK/Canada/South Africa...

PCB Supplier Shenzhen, China, PCB Manufacturer, Turnkey services

-

PCBSINO is the Top 5 PCB manufacturer company in China.

PCBSINO do rapid Prototype within 24 hours. our rigid PCB like MCPCB and Rogers PCB, FR4, High TG FR4, Rogers 4003, 4350,Al Aluminum metal Core MCPCB, Al2O3 Ceramic,Taconic,Halogen Free material, CEM-3, Fr2, CEM-1, CEM-2, 94VO, Rogers HF material, Polymide, etc.

PCBSINO making many type electronic product for our customer, Our turkey services team can source original components part for your project(Digikey/Mouser/RS...), senior Electronic engineer will follow each step of the production to solve any PCB problem and our team will do final function test in PCB house.

Express PCB |

|

Rigid PCB Rapid Prototype,24 hours |

| Fr4 PCB |

|

prototype Lower to 15USD ! |

| Rapid Prototype |

|

Fr4 Rigid PCB Rapid Prototype China, |

MCPCB |

|

MCPCB Manufacturer China, Shenzhen |

| Aluminum PCB: |

|

Aluminum Metal Core PCB manufacturing, Fabrication |

| Aluminum PCB: |

|

single side, double side MCPCB, 0.5-5mm or more |

Rogers 4350B |

|

Rogers 4350,Rogers 4003 Manufacturing |

| Rogers 4350B |

|

Rogers 4350B,4003C PCB Manufacturer |

| Ro4350B |

|

Rogers High Frequency PCB Manufaturing China |

Turnkey Services |

|

Turnkey PCB Assembly Services, |

| Turnkey services |

|

Print circuit board Manufacturing, Turnkey Services |

| Turnkey Assembly |

|

Through Hole PCB components wave soldering Assembly |

Radio base station Rogers PCB aplication

-

Radio base station Rogers PCB aplication

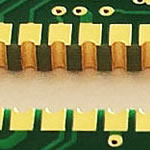

2 Layer RF Design Rogers Radio Pcb Circuit Board RF/Microwave PTFE-based Materials

Key specifications/special features:

Rogers PCB

Rogers 4350B, Roger3003, Rogers4003,Roger 5880 and more material on stock

PCB thickness: 0.2-2mm+/-10%

Final copper: 0.5-10oz

Min hole: 0.2mm

Min line width/space: 4/4mil

Min hole copper: 20μm/25μm

Solder mask: green/blue/red/black/gray/white

Legend: white/black/yellow

Surface: OSP/HAL lead-free/immersion gold/immersion tin/

immersion silver/flash gold/hard gold

Outline: rout and score/V-cut

E-test: 100%

Certificates: UL, SGS, RoHS Directive-compliant, ISO

Files: Gerber Protel DXP Auto CAD PADs eagle

Testing: flying probe test, E-test, X-ray Inspection, AOI

Available substrates:

RO4350B RO4003C TLX-8 (TACONIC) F4B Woven Glass-Reinforced PTFE

4mil(0.1mm) 8mil (0.203mm) 20mil(0.5mm)

10mil(0.254mm) 12mil(0.3mm) 30mil(0.762mm)

13.3mil(0.338mm) 20mil(0.508mm) 40mil(1.0mm)

20mil (0.508mm) 32mil(0.813mm)

30mil(0.762mm) 60mil(1.524mm)

60mil(1.524mm)

RT/duroid high frequency circuit materials are filled PTFE (random glass or ceramic) composite laminates for use in high reliability, aerospace and defense applications. It aslo used in RF Mcrowave wireless Antenna , microwave radio . It announced TerraGreen, a halogen-free, ultra-low loss, RF/microwave/high-speed material. TerraGreen is engineered for such high-performance applications as power amplifier boards for 4G LTE base stations.

1 Telecom: transmitter. Receiver. Oscillator. Antenna.

2 Satellite receiver

3 Global location system, amplifier, satellite telecom

4 Microwave transmission

5 Automobile telephone

6 Measure apparatus, LSI inspector, analyser, signal oscillator

7 High frequency teletcom, high speed transmission, high security, high transmission quality, high

One of the main advantages of the new RO4230 laminate is that it is fully compatible with conventional FR4 processing and does not require special treatments needed on PTFE-based laminates for plated-through-hole preparation. Thus, it is an affordable alternative to PTFE antenna materials, allowing designers to optimize performance/ price benefits.

Thermal Characteristics

The resin system of the RO4230 dielectric material is designed to provide thermo-mechanical properties critical to antenna design. Its coefficient of thermal expansion (CTE) in both the X and Y directions is similar to that of copper, thus minimizing the thermal effects of environmental conditions by reducing the stresses that can lead to warpage of the printed circuit board antenna. RO4230 material’s glass transition temperature exceeds 280°C; this, coupled with low Z-axis CTE, provides excellent plated-through-hole reliability. In addition, its increased thermal conductivity over equivalent PTFE woven glass materials (0.44 W/m/K) allows for antenna designs with increased power handling capability.

Electrical Properties

The following ten points illustrate the key benefits in printed circuit board design which you may wish to consider when seeking a design solution:

1. Printed circuit boards are single monolithic copper circuits. Generally, there is only one electrical connection from the input connector to the printed circuit which should result in greater stability of performance. It avoids the use of metal-to-metal junctions which can degrade over the life of the antenna due to oxidation, corrosion, and mechanical stress and lead to instability in terms of patterns, gain, return loss, and PIM (Passive Inter-modulation) values.

2. Typically manufacturing imperfections show up in the elevation gain patterns of these panel antennas. These patterns are affected by the amplitude and phase of the signals at each of the elements. The phase and amplitude control offered by the printed circuit feed network is far better than even the most painstaking cable assembly process which offers variations in cable length of ± 100 mils. At 2 GHz a 1 degree phase error is caused by only 13 mils of length variation from nominal. At only 50 mils the phase error is about 4 degrees. The performance variation caused by cold flow of the PTFE dielectric in cable bends and terminations is eliminated. Over the life of the antenna the change can range from 5 to 30 degrees for each bend.

3. With microstrip printed circuit power distribution networks, the fields are tightly coupled through the dielectric circuit material due to the higher dielectric constant and close proximity of the line to the ground plane. The feed lines then have a minimal effect on the far field pattern of the antenna.

4. Microstrip-fed, printed circuit antennas have proven to be capable of 200 and 500 watt power levels in cellular applications. This is due to the close proximity of the antenna chassis, which acts as a heat sink.

5. The assembly process for PCB antennas is clean and repeatable. Common or standardized assemblies and tooling can be developed for a large number of antenna types through the use of generic circuit board outlines. There can be a lot of assembly commonality from one design and frequency set to another.

6. PCB antennas have only a fraction of the number of parts found in a metal or cable antenna. Assembly time and opportunities for error are therefore far lower with a printed circuit antenna. A typical 2 meter PCB antenna would have 20 fewer parts than a cabled or bent metal antenna.

7. Printed circuit designs lend themselves to speed in prototyping. Through the uses of automated CAD tools and an extensive PCB manufacturing infrastructure, it is routine to obtain a PCB prototype of a new PCB design variation in 3 to 5 days. Antenna designs are typically iterative, requiring many cycles of trial and adjustment in order to satisfy all design criteria, such as gain pattern, VSWR, beam width, side lobe levels, null fill, etc. The same kind of design iterations on all metal, air dielectric, antennas require longer lead times due to the need to produce manufactured parts. Economical production of an all metal, air dielectric, antenna requires the use of extensive production tooling. This tooling is generally expensive — costing tens of thousands of dollars — and can be a long lead item. As a result, time to market with a PCB antenna is much shorter and tooling costs are minimal. For PCB antennas to reach a production state the required time is usually around 2-4 weeks while tooling for a cabled or bent metal antenna can require 6 - 12 weeks. Artwork for producing PCB antennas including multi-up charge are about $200.00 per antenna while the tool cost for cable and/or bent metal can easily exceed $1000.00 per antenna.

8. PCB manufacturing is ideally suited to tighter tolerance requirements as frequency increases and geometries become smaller.

9. Printed circuit designs can be produced with very low profiles leading to less wind loading on the support tower structure.

10. Use of printed circuit designs make it easier to integrate other components (filters, amplifiers, etc.) into the antenna. This is gaining greater attention because of the desire for 'smart' antennas and multi-band antennas or distributed amplification built into the antenna.

The Durel Division of Rogers Corp. will be showcasing its Printed Electronics and EL Lighting Solutions at the upcoming Printed Electronics show, December 2-3, in San Jose, CA (Rogers booth #43). With over 20 years of design and high volume manufacturing experience in printed electronics, Rogers Durel offers comprehensive...

Rogers will be showcasing new advanced packaging material and thermal management solutions at the upcoming IMAPS show (November 4-6, Providence, RI). Rogers' Advanced Circuit Materials Division (ACMD) will feature its new RO2808 high frequency circuit material. With a dielectric constant of 7.6, the ceramic-filled PTFE material offers the stability...

Printed circuit antennas become more attractive as the level of antenna complexity increases. Cross-polarized antennas, for example, are really two linear antennas in one. The complexity presented by two feed networks and the number of elements required for the two polarizations present a significant challenge to the cable and air dielectric design methods. Parts count will increase accordingly, making assembly more complex. With the printed circuit antenna, parts count and complexity do not really increase. Both feed networks can be printed on a single circuit. Active antennas with distributed amplification also lend themselves to the printed circuit technique. The amplifier circuits can be incorporated on the same circuit board used for the feed network and/or radiating elements.

To truly be an advantageous replacement for existing antenna circuit material requires that its electrical properties closely match the needs of antenna designers so existing antennas require minimal or no redesign. RO4230 laminate has a dielectric constant (Dk) of 2.98 ±0.05 and a loss tangent (Df) of 0.0020 measured at 2.5 GHz and 0.0023 at 10 GHz. These values allow antenna designers to realize desired gain while minimizing signal loss in the feed network. In addition, RO4230 material has demonstrated low PIM performance, with values better than –155 and up to –162 dBc using two 43 dBm swept tones at 1900 MHz. Figure 2 shows an insertion loss comparison with PTFE/woven glass, RO4350 laminate and a competitive thermoset material. Figure 3 shows the effect of the RO4230 material’s improved thermal conductivity.

Conclusion

The market has had a need for an improved material for use in cellular base station antennas, satellite radio applications and WiMAX antennas, as well as others. RO4230 laminate was designed to provide an enhanced price/performance benefit over Dk 3.0 PTFE/woven glass materials.

RO4230 laminate is available in standard thicknesses of 0.030", 0.040" and 0.060" with 1 oz. electrodeposited copper cladding. Standard panel sizes are 24" × 18", 24" × 36" and 48" × 36". Nonstandard panel sizes are available up to 48" × 108".

memory transaction

Space Saving Circuitry

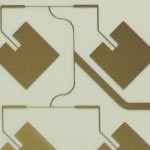

Patch Antennas

Satellite Communications Systems

Power Amplifiers

Aircraft Collision Avoidance Systems

Ground Radar Warning Systems

Datalink on cable systems

Remote meter readers

Power backplanes

LMDS and wireless broadband

Base station infrastructure

System Printed Board High Frequency Rogers PCB Board Rogers high frequency pcb widely used in the area of high technologies like communication device,Electronics,Aerospace,Military industry and so on. we have accumulated abandunt experiences in the line of high frequency microwave business for which widely apply to power divider,combiner,power amplifier,line amplifier,base station,RF antena,4G antena etc.

We have sufficient rogers material raw as follow:RO4003C,RO4350B,RO4360,RO4533,RO4535,RO4730,RO4232,RO4233,RO3003,RO3006,RO3010,RO3035,RO3203,RO3206,RO3210,RO3730,RO5780,RO5880,RO6002,RO3202,RO6006,Frequently-used is 4003C,4350B,5880

So we can do pcb circuit board with your detail requirements in the case of you send us gerber files or any other files

Application:

High Power Amplifier, TMA, TMB, LNA: for GSM, UMTS, 3G, PCS, PCN, WCDMA, TD-SCDMA, EDGE, CDMA2000

Repeater

Phase Shifter

Antenna

Filters and Coupler

Passive Components

Shenzhen Xinchenger Electronics is a leading manufacturer of high frequency pcb circuit more than 6

years in shenzhen.

We concentrate on high difficult,high precision pcb circuit board production.3mil line space and width is

available here

If you have any needs,please do not hesitate to send us inquiry.

Radio-frequency (RF) and microwave (MW) circuits can be found in countless wireless products from handheld devices for medical and industrial applications to advanced communications systems for base stations, radar and global positioning. The success of these high-speed products begins at the product design stage when the PCB laminate materials are selected. NCAB Group works with the product design team to insure that the project’s cost/performance targets can be met by providing information on material options, relative costs and DfM considerations. Once the design has been completed, NCAB Group follows the boards from prototype through to production where key process variables such as line widths and dielectric spacing are measured and controlled to insure the product meets the designed requirements and delivers consistent performance throughout the products life cycle.

Rogers Corporation Advanced Circuit Materials Division recently introduced improved high frequency materials to address several market needs. The improved RO4700JXR Series antenna grade laminates were designed for use in base station, RFID and other antenna designs and combine low-loss dielectric with low-profile copper foil for reduced passive intermodulation (PIM) and low insertion loss. The specially formulated RO4700JXR thermoset resin system incorporates a hollow microsphere filler resulting in a light weight, low density laminate, which is approximately 30% lighter weight than woven-glass PTFE materials. In addition, RO4725JXR (2.55Dk) & RO4730JXR (3.0 DK) laminates provide a lower cost solution for high frequency circuit boards used in base station and other antennas.

RO4700JXR series RoHS-compliant laminates are compatible with standard PCB fabrication techniques and plated-through-hole (PTH) processing. Designed for base station and other RFID antennas, the proprietary, halogen-free laminates support longer drill tool lifetimes than other filled materials, reducing fabrication costs.

Rogers Corporation’s Advanced Circuit Materials Division has received board approval to install a RO3000 dielectric production line to increase capacity in Chandler, Arizona. Dielectric is a specialty polymeric substrate that is laminated at high temperature between two sheets of copper foil to create PCB material. “We have decided to accelerate our investments in capacity expansion to support the strong global demand for RO3000 laminate materials, such as those used in 4G/LTE Base Station applications,” said Jeff Grudzien, vice president of Advanced Circuit Materials. “In addition, this investment puts us in a strong position to meet the future material needs of a growing number of Radio Frequency (RF) designs using RO3000 materials in 77 GHz automotive sensors and Mobile Internet Devices such as tablets and smart phones. It is an exciting time for us at Rogers given the number of customers and applications that are seeking the advantages and unique properties that our high frequency circuit materials provide.” About RO3000 Laminate Materials RO3000 high frequency circuit materials are ceramic-filled PTFE composites intended for use in commercial microwave and RF applications. This family of products was designed to offer exceptional electrical and mechanical stability at competitive prices. RO3000 series laminates are available without woven fiberglass reinforcement providing circuit materials with unique, electrically isotropic properties compared to competitive material offerings. In addition, RO3000 laminates are available in a wide range of dielectric constants with a low Thermal Coefficient of Dielectric Constant (TCDk) for electrical stability over a wide range of temperatures. About Rogers Corporation Rogers Corporation is a global leader in engineered materials to power, protect, and connect our world. With more than 182 years of materials science experience, Rogers delivers high-performance solutions that enable clean energy, internet connectivity, advanced transportation and other technologies where reliability is critical. Rogers delivers Power Electronics Solutions for energy-efficient motor drives, vehicle electrification and

Surface finish Immersion gold

Delivery time 3 7days

Min order 1pcs

Rogers laminate widely used in Microwave/RF filedRF pcb(radio frequency pcb)

RF electromagnetic wave is defined by the application division specifically refers to electromagnetic waves with a certain wavelength can be used for radio communication. Frequency range defined confusing information has 30MHz to 3GHz there 300MHz to 40GHz and microwave overlap Another kind is by definition spectrum allocation refers to the wavelength of electromagnetic waves within 1m range from 1 trillion m to its corresponding frequency from 30Hz to 300MHz radio frequency (RF) and microwave frequency boundaries rather vague and with advances in device technology and design methods which had been changed. RF PCB and Features

PCB design considering the particularity of the main circuit model considering the PCB transmission line. Since the transmission line using the line lumped parameter circuit model and distributed parameter circuit model can be considered l / 955 8805 0. 05 (where l is the geometrical length 955 is the operating wavelength). Defined in this specification refers to the transmission line structure RF link distributed parameter model using an analog signal circuits. PCB line length rarely more than 50cm it is considered the lowest frequency of 30MHz analog signal can be As more than 3G is generally considered to be pure microwave consider this far down consider the production process element spacing up to 0. 5mm can also be considered given the highest frequency at 30GHz the feeling of little significance.

In summary we can consider RF PCB PCB can be defined as the frequency range of 30MHz to 6GHz analog signal having but the specific use or distribution of lumped parameter model can be determined according to the formula. High frequency pcb RF material

to get a lot more premium sports content, as Sportsnet will launch a new, all-sports radio station – Sportsnet 650 – in Vancouver this fall.

Rogers Media will acquire the Vancouver AM station CISL from Newcap Inc. (a wholly-owned subsidiary of Newfoundland Capital Corporation Limited), subject to approval from the Canadian Radio-television and Telecommunications Commission (CRTC), and will change the station’s format to all-sports. The transaction is expected to close in summer 2017.

“We are excited to build upon our strong radio brands in the Vancouver market. With Vancouver being such a passionate sports town, there is a strong appetite for all-sports radio that delivers engaging conversation, wide-ranging opinion, and top-tier live sports content,” said Julie Adam, Senior Vice President of Radio, Rogers Media

Sportsnet 650 will have year-round top-tier sports content, including Vancouver Canucks and Blue Jays games, plus the MLB post-season. Additional programming details and on-air personalities will be announced in the coming months.

“Vancouver has an incredibly loyal fan base, and this is a natural fit to expand our Sportsnet offering,” said Scott Moore, President of Sportsnet, Rogers Media. “Sportsnet has been strongly committed to the Vancouver community since the network’s inception in 1998 when we first began televising Canucks games.”

Sportsnet 650 marks the third all-sports radio station for Sportsnet, alongside stations Sportsnet 590 The FAN in Toronto and Sportsnet 960 The FAN in Calgary.

Said Al Dark, Senior Vice President of Sales, Rogers Media: “Sportsnet is Canada’s number one sports brand, and we are thrilled we have another platform for our advertisers to reach their target audiences.”

The AM 650 station will continue to be broadcast in its current format until Sportsnet 650 radio launches in the fall.

Advantage:

Exceptional Interlaminar Bond

Low Moisture Absorption

Enhanced Dimensional Stability

Low Z-Axis Expansion

Stable Dk Over Frequency

Circuit Miniturization

Increased Flexural Strength

Aluminium backed laminates provide a ready made solution for PCBs requiring superior thermal management compared to conventional FR4-based materials. Benefits are;

Faster heat removal from high power density devices

Lower peak temperature compared with standard PCB substrates

Superior heat dissipation beyond the capability of standard PCB substrates

2 W/mK thermal conductivity, 6-8 times higher than FR4

Uniform conductivity in vertical and horizontal axes as dielectric contains no glass layer

Extends life expectancy of power devices by reducing device temperature

Designed for performance ,sensitive, high volume applications

Low dielectric tolerance and low loss

• Excellent electrical performance

• Allows applications with higher operating frequencies

• Ideal for broadband applications

Stable electrical properties vs.frequency

• Controlled impedance transmission lines

• Repeatable design of filters

Low thermal coeffi cient of dielectric constant

• Excellent dimensional stability ,Low Z-axis expansion

• Reliable plated through holes

Low in-plane expansion coeffi cient

• Remains stable over an entire

range of circuit processing temperatures

Volume manufacturing process

• RO4000 laminates can be fabricated using standard glass epoxy processes

• Competitively priced CAF resistant

Some Typical Applications:

• Cellular Base Station Antennas and Power Amplifi ers

• RF Identifi cation Tags

• Automotive Radar and Sensors

• LNB’s for Direct Broadcast

Rogers material features and Benefits(6000series):

• High dielectric constant for circuit size reduction

• Low loss. Ideal for operating at X-band or below

• Low Z-axis expansion for RT/ duroid 6010LM. Provides reliable plated through holes in multilayer boards

• Low moisture absorption for RT/duroid 6010LM. Reduces effects of moisture on electrical loss

• Tight, and thickness control for repeatable circuit performance

Some Typical Applications:

• Patch Antennas

• Satellite Communications Systems

• Power Amplifi ers

• Aircraft Collision Avoidance Systems

• Ground Radar Warning Systems

Rogers substrate Features(Rogers5000):

• Lowest electrical loss for reinforced PTFE material

• Low moisture absorption

• Isotropic

• Uniform electrical properties over frequency

• Excellent chemical resistance

Some Typical Applications:

• Commercial Airline Broadband Antennas

• Microstrip and Stripline Circuits

• Millimeter Wave Applications

• Military Radar Systems

• Missile Guidance Systems

• Point to Point Digital Radio Antennas

Sufficient stock:

We have sufficient rogers material raw as follow:RO4003C,RO4350B,RO4360,RO4533,RO4535,RO4730,

RO4232,RO4233,RO3003,RO3006,RO3010,RO3035,RO3203,RO3206,

RO3210,RO3730,RO5780,RO5880,RO6002,RO3202,RO6006,

Frequently-used is 4003C,4350B,5880

So we can do pcb circuit board with your detail requirements in the case of you send us gerber files or any other files

For furhter information, please feel free to contact us, www.pcbsino.com