High Speed PCB Prototype Multilayer PCB Manufacturer China;

Contract manufacturing of High Speed PCB, Mass Production, Fabrication

High Speed PCB, Low cost,Shenzhen,China/USA/UK/India/South Africa

MICROWAVE & RF PRINTED High speed CIRCUIT BOARDS

-

MICROWAVE & RF PRINTED High speed CIRCUIT BOARDS

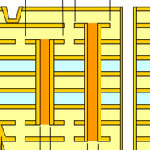

In order to meet increasing demands for Microwave & RF Printed Circuit Boards for our customers all around the world, we have increased our investment over the last few years so that we have become a world class manufacturer of PCB's using high frequency laminates.

These applications typically require laminates with specialized electrical, thermal, mechanical, or other performance characteristics that exceed those of traditional standard FR-4 materials. With our many years of experience with PTFE-based microwave laminate, we understand the high reliability and tight tolerance requirements of most applications.

High speed PCB |

|

High Speed PCB Manufacturing,Fast PCB Prototype |

| RF frequency |

|

High Speed PCB Prototype |

| blind via |

|

impedance control high speed PCB |

RF frequency |

|

High Speed PCB Manufacturing |

| High Frequency |

|

High Speed PCB Prototype |

| Buried via |

|

rogers material High speed PCB |

High speed PCB |

|

High Speed PCB Manufacturing |

| RF PCB |

|

Multilayer High speed PCB Manufacturing |

| Impedance control |

|

RF High frequency PCB Fabrication |

Impedance control |

|

Multilayer High speed PCB Manufacturing |

| Rf PCB |

|

2-40 layer, blind/buried via high speed PCB |

| High speed PCB |

|

Carbon/Silver Ink Printing or Gold-plated Surface |

Impedance control |

|

RF High frequency PCB Fabrication |

| High Frequency |

|

Flexible PCBs with Immersion Silver Surface Treatment |

| High speed PCB |

|

2-40 layer, blind/buried via high speed PCB |

Selecting the most appropriate PCB materials for your ultra high speed digital applications

-

Selecting the most appropriate PCB materials for your ultra high speed digital applications

Do you remember a time when PCB material selection was simple? For run of the mill applications choose "vanilla" flavored FR4 and for high speed applications, perhaps either a ceramic loaded core or PTFE based substrate. Whilst these two options still exist at the extremes of the market the last few years have witnessed a stream of new "mid market" core and prepreg materials which temptingly offer increased high speed performance and more standard processing methods than more exotic materials.

There is a place for all the above materials in the market but both the EE putting together the "platform specification" for the new design and the PCB fabricator responsible for its realisation are faced with a bewildering array of materials with a mix of choices from ease of processing through to reliability requirements and onwards to signal integrity capability. This application note deals with the signal integrity angle and how to use the Si9000e to make the best choices for material selection when trading cost versus signal integrity performance.

How to Select PCB Materials For High-Speed Digital Circuits

-

How to Select PCB Materials For High-Speed Digital Circuits

PCBSINO is High Speed pcb manufacturer,welcome to choose PCBSINO as your High speed High Frequency pcb supplier.

Digital circuits continue to conquer higher speeds, with components such as microprocessors and signal converters routinely performing billions of operations per second. True, high-speed digital circuits can be flawed by such things as impedance discontinuities in transmission lines and poor plated-through-hole (PTH) interconnections between layers on multilayer circuit boards. But they can also be hurt by less-than-ideal choices of PCB materials for those high-speed-digital circuits. Which generate the question: “What are the key parameters to consider when selecting a PCB material for a high-speed-digital circuit application?”

Fits Your High-Speed Circuits?

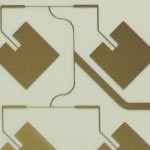

Sorting through the specifications helps when selecting a circuit material for microwave, millimeter-wave, and even high-speed-digital circuits.

From a technology standpoint, Riley pointed out that this will mean higher frequency, wider bandwidth, and higher efficiency power amplifiers (PAs). Other needed components will include low noise floor LNAs, quantized phase shifters and ultra-low jitter clocks. Low-cost mm-wave packaging must also be available, as will ultra-high speed and low power A dc/D ac, high-gain directional antennas and beamforming and very high data rate serial links—like SerDes, TIA, and optical drivers.

PCBSINO offers a wide range of High-speed Digital (HSD) materials that deliver superior performance and CAF resistance. These low-loss materials are targeted for applications that require high reliability and signal integrity. PCBSINO also offers halogen-free HSD materials for green electronics.

A successful high-speed digital product is reliant upon the PCB material selected. Several factors, such as the maximum data rate, the length of the high-speed digital channel, as well as thermal and processing considerations should be taken into account when choosing a material.

Features:

Excellent Conductive Anodic Filament (CAF) performance

Superior thermal robustness

Lead-free assembly

Typical Applications:

Automotive

Communications and networking servers

Wireless handsets and infrastructure

Internet infrastructure

Test & measurement

Backplanes

What is High Frequency (HF) PCB?

-

What is High Frequency (HF) PCB?

Electronic devices with high frequency is the developing tendency nowadays, especially in wireless network. Satellite communication growing rapidly, information products move towards high speed and high frequency. Thus developing new products always need to use high frequency substrate, satellite system, mobile telephone receiving base station and so on, these communication products must use high frequency PCB.

The features of high frequency PCB as following:

1. DK should be small and stable enough, usually the smaller the better, high DK may lead to signal transmission delay.

2. DF should be small, which mainly affect quality of signal transmission, the smaller DF could make smaller signal wastage accordingly.

3. The thermal expansivity should be the same with copper foil as much as possible, because the difference will lead to copper foil separated in the changes of cold and heat.

4. Water absorptivity must be low, high water absorptivity will affect DK and DF when in the wet environment.

5. Heat resisting property, chemistry resisting, impact endurance, peel off resisting must be good.

For furhter information, please feel free to contact us, www.pcbsino.com