Box Build Assembly-enclosures and instrument panels

box build assembly and mechanical engineering capabilities;

electrical and mechanical box build assembly services

box builds, box build assembly & panel builds

-

Box build assembly and mechanical engineering capabilities are integral to our turnkey electronics manufacturing solutions.

PCBSINO provides a full electrical and mechanical box build assembly service tailor made for your requirements saving you both time and money

PCBSINO is a leading box build assembly contract manufacturer. OEMs count on PCBSINO for custom box build assemblies built right & delivered on time

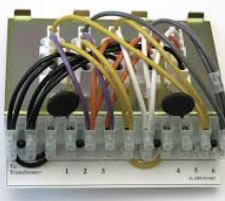

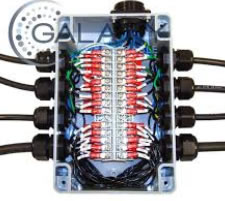

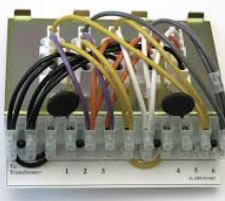

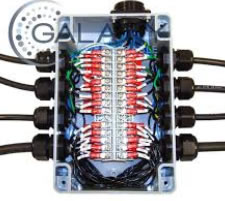

Box-build: sometimes, also called systems integration, assembly work other than printed circuit board (PCB) production. The electromechanical assembly process involving enclosure fabrication, installation of sub-assemblies and components, and installation and routing of cabling or wire harnesses.

Box build systems integration

|

|

Box build systems integration

|

|

Box build systems integration

|

Box build systems integration

|

|

Box build systems integration

|

|

Box build systems integration

|

Box build systems integration

|

|

Box build systems integration

|

|

Box build systems integration

|

box build assembly services

-

PCBSINO Provides a full electrical and mechanical box build assembly service tailor made to your requirements.

Electromechanical assemblies and sub assembly

including component procurement, product engineering, production operations, testing and approvals

Box build and panel build

our services and expertise in box build and panel build has been utilised across Defence, Electronics, Energy, Marine and Medical industries, and are highly adapatable to meet the requirements of each individual customer.

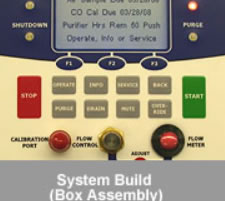

project introduce:

Our engineering team worked closely with the customer defining the material requirements for the interface box build. All the components and materials included in the BOM were reviewed for possible alternatives that would improve either the assembly process or the quality of the end product. As a result, we were able to provide a number of low-cost improvements. For instance, the original sample unit had the indicator LEDs in the lid of the enclosure mounted directly into holes and epoxied in place. We recommended the use of a black polypropylene mounting clip to install the LEDs in the enclosure lid, which provided multiple improvements. The mounting clip offered physical protection for the LED as it utilized a recessed installation rather than the bare LED sticking completely up out of the enclosure. The black clip also surrounded the LED with a dark contrast that improved the visibility of the LED which was a specific improvement required by the customer.

For furhter information, please feel free to contact us, www.pcbsino.com