Automobile power controller Aluminum mcpcb aplication

China PCB Manufacturing, Shenzhen PCB Manufacturer, Making Circuit boards

PCB Contract manufacturer, PCB Fabrication, Turnkey assembly services

Buy Print circuit board, customer: /USA/UK/Canada/South Africa...

PCB Supplier Shenzhen, China, PCB Manufacturer, Turnkey services

-

PCBSINO is the Top 5 PCB manufacturer company in China.

PCBSINO do rapid Prototype within 24 hours. our rigid PCB like MCPCB and Rogers PCB, FR4, High TG FR4, Rogers 4003, 4350,Al Aluminum metal Core MCPCB, Al2O3 Ceramic,Taconic,Halogen Free material, CEM-3, Fr2, CEM-1, CEM-2, 94VO, Rogers HF material, Polymide, etc.

PCBSINO making many type electronic product for our customer, Our turkey services team can source original components part for your project(Digikey/Mouser/RS...), senior Electronic engineer will follow each step of the production to solve any PCB problem and our team will do final function test in PCB house.

Express PCB |

|

Rigid PCB Rapid Prototype,24 hours |

| Fr4 PCB |

|

prototype Lower to 15USD ! |

| Rapid Prototype |

|

Fr4 Rigid PCB Rapid Prototype China, |

MCPCB |

|

MCPCB Manufacturer China, Shenzhen |

| Aluminum PCB: |

|

Aluminum Metal Core PCB manufacturing, Fabrication |

| Aluminum PCB: |

|

single side, double side MCPCB, 0.5-5mm or more |

Rogers 4350B |

|

Rogers 4350,Rogers 4003 Manufacturing |

| Rogers 4350B |

|

Rogers 4350B,4003C PCB Manufacturer |

| Ro4350B |

|

Rogers High Frequency PCB Manufaturing China |

Turnkey Services |

|

Turnkey PCB Assembly Services, |

| Turnkey services |

|

Print circuit board Manufacturing, Turnkey Services |

| Turnkey Assembly |

|

Through Hole PCB components wave soldering Assembly |

Automobile power controller Aluminum mcpcb aplication

-

Automobile power controller Aluminum mcpcb aplication

When the thermal heat dissipation requirements of a design are very high, using an Aluminum backed PCB is a highly effective solution. This kind of design is capable to better translate thermal energy away from your design's components, therefore control your project's temperature. It is typically on the order of ten times more efficient at removing thermal energy from circuit components than the equivalent fiberglass backed board. This significantly higher level of thermal dissipation allows for higher power and higher density designs to be implemented.

Moreover, Aluminum Backed PCBs are finding applications in high power/high thermal heat dissipation applications. Originally tasked for use in high power switching supply applications, they have become very popular in LED applications. Examples of LED applications include traffic lights, general lighting and automotive lighting. The use of an aluminum backed design (LED PCBs) allows for a higher density of LEDs in the board design and for the mounted LEDs to be driven at higher currents while still remaining within temperature tolerances. Using an Aluminum backed design can allow designers to decrease the safety margin used with power LEDs and derate said LEDs less than would be the case with a conventional PCB design. As with all components, the lower the operating temperature of the LEDs in a design the longer those LEDs can be expected to operate before failing.

Other applications for Aluminum backed PCB designs include high current circuitry, power supplies, motor controllers and automotive applications. Aluminum backed PCBs are the perfect thermal heat dissipation solution for any design that utilizes high power surface mount ICs. Additionally, they can eliminate the need for forced air and heat sinking, then ultimately lower design cost. Essentially, any design that can be improved by higher thermal conduction and better temperature control is a possible application for an Aluminum backed PCB.

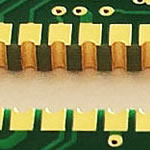

Circuits on metal substrate (aluminum) for the power applications in IMS technology.

IMS Technology is well suitable for applications where electronics is handling very high currents, up to several hundred Ampere, with need of thermal dissipation and mechanical strenght.

Andwin Circuits is a leading of

Double sided aluminum pcb manufacturer.

Have capability to Provide double sided aluminum pcb,

2 layers doble face SMT PCB with PHT(Plate through Hole) via holes,

2 layers 1 face SMT PCB with PHT via holes for customers.

Double sided MCPCB Application:

.Auto

.Equipment

.Power supply

.Communication

.LED Lighting

And other product which need thermal out.

Follow is Structure of Double Sided MCPCB detail:

1. Stack up of 2 Layers Double sided MCPCB

PCBs for the Automotive industry require high reliability, long life service, at a highly competitive rate. The sector consists of passenger vehicles, trucks, trailers, sub assemblies, and dealer support systems.

Amitron provides printed circuit boards that offer a wide range of materials, composites, and construction, that perform well in the rigors of the automotive world. We produce display PCBs, circuits for engines and various electronic components such as stereo systems.

High Temperature laminates, copper and aluminum substrates perform very well in harsh automotive applications. Amitron supplies a vast array of laminates with copper weights that are unrivaled in our industry. Differential copper plated is unique to Amitron. Twenty ounce copper on side one and one ounce copper on side two would be a typical configuration of differential copper. This technique offers signal application on one side and high power on the other. Amitron is ISO 9001-2008 certified.

2. Stack up of 2 Layers 1 SMD Face of MCPCB

MCPCB (Metal Clad Printed Circuit Board) technology was initially designed in the 60’s for high power applications. Known also as MPCB (Metal Printed Circuit Boards) or IMS (Insulated Metal Substrate). Since then it has been used widely in the LED industry, where the benefits of reduced junction temperatures have been realised.

With the boom of the LED lighting industry in the last 10 years, the demand for metal clad PCBs has risen dramatically. Metal circuit technology is now being used in all sorts of applications ranging from industrial to automotive. With this we have seen an influx of material providers influencing the market with new technology. From the 2-3 material providers years ago to the many we see on the market today.

The advantage of using metal clad material for PCB production as opposed to more traditional materials such as FR4 and CEM is simply to do with the efficient removal of heat. The dielectric insulating material in metal clad materials is designed to have a much superior thermal conductivity than that of FR4—generally ranging from 1W/m-K to 9W/m-K. Allowing for efficient heat removal.

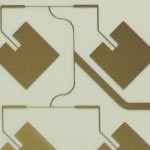

The material used to fabricate metal clad PCBs is made of 3 parts; The base layer, the dielectric, and the copper foil –

Choosing the Right Solution for Your Needs

Flexible PCBs are used in a variety of different applications such as portable electronics, devices, hard dish drives and desktop printers

Rigid PCBs are designed for applications that have complicated circuit layouts or need many electric components mounted. This type of PCB offers high durability, reliability and a long life cycle, which is why they are often used in LEDs, as well as automotive, medical, HVAC, fitness equipment and industrial applications.

Rigid-flex PCBs maximize space and greatly improve reliability. This type of PCB is designed for advanced electrical applications such as testing equipment, tools and automobiles. In addition, rigid-flex PCBs are used in medical devices such as pacemakers, because of their space and weight reduction capabilities.

Aluminum/metal clad circuit boards are used a base metal material to assist with the heat dissipation of the circuit board. Metal clad PCBs are widely used in light emitting diodes (LED) technologies to assist with heat dissipation and produce a specific illumination along with power converters in the telecom, industrial, high voltage regulator, power supplies, hybrid/electric motor control applications and photovoltaic products. The thickness of metal cores in PCB base is typically 30–125 mil, but thicker and thinner plates are available based on the customer’s application needs.

Copper clad PCB/heavy copper PCBs have the ability to dissipate heat away from components, which is why this type of PCB is in high demand. With increasing power requirements of products today, a copper PCB could be the right choice for your application. Common applications of a copper clad PCB/heavy copper PCB include power converters for telecom, industrial, power supplies and high voltage regulators, hybrid/electric motor control applications and general lighting applications

MC PCB means metal core printed circuit boards. why use metal,not FR4/CEM-1 or others? All is to get high thermal conductivity. The most MC PCB is Aluminum PCB, Aluminum has good heat transfer and dissipation ability, but also cheaper than copper based PCB.Many customers asked a quote for MC PCB but without the thermal requirements.If you know the thermal conductivity is the most most important thing for MC PCB,then

you will know why the price is so difference. Normal thermal is from 0.8-2.00 W/m.k,and higher can up to 8.0 W/m.k,even more if you need ,but ,are you sure ? When we quote to you ,we have to ask you the thermal conductivity,it is not only about cost but your product.Many factories used low thermal ,can you use the boards?

MC PCB uses in LED lights,Industrial power equipment,Cars,Power,etc. Bergquist is the top quality metal core material but top cost as well.

Thermal Conductive Board (TCB), or Insulated Metal Substrate (IMS), provides the advantages of high thermal conductivity, reliability and solder heat endurance. The TCB substrate is a sandwich structure, which includes layers of conductor, insulator and metal base.Traditionally, this insulator is made of epoxy, epoxy filled glass fiber, polyimide, or other dielectric materials. However, these kinds of insulators could not meet the requirement in high-power electronic devices. The heat generated by these devices will accumulate, and

the life time and reliability of the end product will decrease.

Visit bergquist to get more information about high thermal.

PTTC (Polytronics) is another top quality but much cheaper than Bergquist in the word ,it is made in TaiWan .visit PTTC.

In some countries,they call MC PCB as IMS PCB.IMS is Insulated Metal Substrates.Most is Aluminum as well.

Standard MC PCB stackup

Shenzhen Shuo Qiang Electronics Co., Ltd., founded in 2011, focus on researching and manufacturing metal based pcb for worldwide customers. With about 200 staff, Monthly manufacturing capacity can reach 13,000 . Factory has passed ISO9001:2008(certificate NO.: 117 13 QU 0199-12 R0M), UL(certificate NO. : E467128), Rohs, CUL safety certification.

Aluminum-based PCB

Copper-based PCB

Ceramic-based PCB

Others: Iron-based PCB/ Stainless steel PCB

An LED is a type of diode that turns electrical energy into light. For those that don’t know, a diode is an electrical component that only works in one direction. Basically an LED is an electrical component that emits light when electricity flows through in one direction, from the Anode (positive side) to the Cathode (negative side).LED is an acronym standing for ‘Light Emitting Diode’. Basically, LEDs are like tiny light bulbs, they just require a lot less power to light up and are much more efficient in producing high light outputs.

LED Types

In general terms, we carry two different types of LEDs: 5mm Through-Hole & Surface Mount.

5mm LEDs

5mm LEDs are diodes inside a 5mm diameter lens with two thin metal legs on the bottom. They are used in applications where a lower amount of light is required. For example, our brightest Cool-White 5mm LED is approximately 27 Lumens and our least bright Surface Mount LED is approximately 100 Lumens. 5mm LEDs also run at much lower drive currents, maxing out at around 30mA, whereas Surface Mount LEDs require a minimum of 350mA. All our 5mm LEDs are from top manufacturers and are available in a variety of colors, intensities and illumination patterns. Through-hole LEDs are great for small flashlight applications, signage and anything where you are using a breadboard as they can be used easily with their leads. Check out our guide to setting up 5mm LEDs for more info on these tiny light sources.

Surface Mount LEDs (SMD)

Figure 1 – Bare Emitter

Surface Mount LEDs are diode(s) that can be placed on a substrate (circuit board) with a silicon dome over the diode to protect it (see Fig. 1). We carry high-power Surface Mount LEDs from industry leaders Cree and Luxeon. Both are excellent in our opinion, that is why we carry them after all. Some prefer one over the other but that comes with experience and knowing what to look for. Cree tends to have higher listed Lumen outputs and are a market leader in the High-Power LED sector. Luxeon, on the other hand, has excellent colors and thermal control.

High Power LEDs come as bare emitters (as seen in Fig. 1) or mounted to a Metal Core Printed Circuit Board (MCPCB). The boards are insulated and contain conductive tracks for easy circuit connections. Our 20mm 1-Up and 3-Up star board designs are the best sellers. We also offer QuadPod’s which can hold 4 high power LEDs on a board slightly larger than the 20mm stars (see Fig. 2). All our high power LED options can be built on a linear design as well. The LuxStrip can house 6 LEDs per foot and are easily connected up to 10 feet long.

Figure 2 – MCPCB Options

Polarity Matters: Wiring LEDs

Electronic polarity indicates whether a circuit is symmetric or not. LEDs are diodes, therefore only allowing current to flow in one direction. When there is no current flow, there will be no light. Thankfully this means that if we wire an LED in backwards, it will not burn the whole system up, it just won’t come on.

The positive side of the LED is the Anode and the negative side is the Cathode. Current flows from the anode to the cathode and never in the other direction, so it is important to know how to tell the anode and cathode apart. For surface mount LEDs this is easy as the connections are labeled, but for 5mm LEDs ook for the longer lead which is the anode (positive), take a look at Figure 3 below.

Among all Metal core PCBs have the important ability to provide effective thermal dissipation for electronic products, Aluminum PCBs is the most common type – the base material consists of aluminum core with standard FR4. It features a thermal clad layer that dissipates heat in a highly efficient manner, while cooling components and increasing the overall performance of the products.

Every rigid and flexible printed circuit board (PCB) design is different, customized to meet the board’s purpose. The same is true for the PCB base material — fiberglass is a popular base material, but aluminum-based PCBs are also very effective in many applications. Aluminum PCBs consist of a metal-based, copper-clad laminate that delivers high performance, including excellent thermal conductivity and electrical insulation.

MOKO is a leading provider of a wide range of printed circuit boards, including metal-base or metal core aluminum PCB’s for the automotive, aerospace, consumer products and medical industries. Here’s our take on the uses and benefits of aluminum-based PCBs. Get Pricing and Lead Time

An aluminum PCB is a metal-based board and its structure is divided into three layers:

Aluminum printed circuit boards are also known as metal base PCBs, and are comprised of metal-based laminates covered by copper foil circuit layers. They are made of alloy plates that are a combination of aluminum, magnesium and silumin (Al-Mg-Si). Aluminum PCBs deliver excellent electrical insulation, good thermal potential, and high machining performance, and they differ from other PCBs in several important ways.

The base layer consists of an aluminum alloy substrate. The use of aluminum makes this type of PCB an excellent choice for through-hole technology, discussed later in this article.

The thermal insulation layer is a critically important component of the PCB. It contains a ceramic polymer that has excellent viscoelastic properties, great thermal resistance, and defends the PCB against thermal and mechanical stresses.

Figure 3 – Finding the anode and cathode of an LED

Color Options

One of the great things about LEDs is the different options and kinds of light you can get from them.

White LEDs

Correlated Color Temperature (CCT) is the process of creating different white light at different temperatures. Color temperature is specified in degrees Kelvin (K), which is a temperature scale in which zero occurs at absolute zero and each degree equals one Kelvin. The lower temperatures from 3,000K to 4,500K tend to be a warmer to neutral white. The higher temps 5,000K+ are the cool whites, also known as ‘daylight white’.

These PCB are widely used in consumer electronics, LED lighting, telecommunication, computer application, industrial control, automobile etc.

Aluminum-based PCB including: LED aluminum pcb, 1.5m supper long aluminum pcb, aluminum pcb with counterbore holes and blind vias, 3oz/4oz heavy copper aluminum pcb ect.

Our featured products and application:

1, Thermoelectric separation copper-based pcb: 150W-300W high power miner lamp and streetlight.

2, COB silver mirror aluminum pcb: after assembly, lights reflectivity up to 98%, luminous efficiency up to 120 LM.

3, COB Silver plated pcb: 3W、5W、7W bulb light and spotlight etc.

4, 1.5m supper long aluminum pcb: factory is equipped with full set of automatic production line of 1.5m supper led tube aluminum pcb, can mass production.

5, Power supply aluminum pcb: factory use Korea Doo Shanlv substrate material aluminum as substrate material, can withstand 6.0KV voltage, widely used in equipment power supply and automatic products.

6, Ceramic-based pcb: thermal conductivity about 26W, withstand high voltage to 8000-10000V.

3_0mm 2oz Bergquist material

thermal conductivity-3.0 W/m.k

Double sided Aluminum board,2 layer 1.5mm,1oz,

White solder mask,Black silkscreen v-groove,rout

Application:LED lamps

T8 LED board,we also offer final T8 product.

Ceramic PCBs can be used in high pressure, high temperature and high frequency applications, such as automotive and consumer electronics industries.

Highly hot and cold impact resistance

Low thermal expansion coefficient

Good thermal and electric conductivity

PTFE teflon PCBs are used when the electrical loss from standard FR4 is not acceptable. This materials low dielectric constant, low loss target and high melting temperature make it the perfect material for printed circuit boards that are to be used at high frequencies in applications such as military, medical, telecommunications and automotive.

THE COPPER FOIL

This is the top copper layer of the material that will eventually be processed into the electrical conductors as per conventional PCBs. Generally 1oz-4oz but can be greater.

THE DIELECTRIC

This is the key part. This is the substance that both electrically isolates the Aluminium base layer from the copper foil, but also allows for rapid heat transfer between the two. It ensures that the heat generated in the components is dispersed to the heat sink as quickly as possible and determines the materials thermal properties. This is the ingredient of the substrate that sets apart a world class material from the cheaper alternatives on the market.

How to make a Double sided Metal (Aluminum) core printed ciruit board?

1. Drill Holes on the bare Aluminum Board

(The holes are larger than your PTH Holes in

Your design)

2. Fill the holes by resin.

3. Laminate dielectric layer

Bettwen Aluminu bare board and two copper foil

4.Drill the holes as your design on the same place

that drilled on first step process

5.Plate through holes

6.Manufacturing trace layer etc….

Then Other process as FR4 PCB boards.

The superior ductility of aluminum metal is an advantage during the work-shop mechanical operations and also makes easy the installation of electronic cards onto the thermal dissipation supports.

IMS means “Insulated Metal Substrate“. The IMS substrate consists in a metal base of several thicknesses, dielectric insulate and a copper conductor layer.

In the IMS power circuits exist many combinations of aluminum thickness, insulate and copper layer.

APPLICATIONS

The power solutions on metal circuits can be matched both in the power branch and light load control branch (lighting).

It’s possible assemble all the SMD components on IMS power circuits with some limitations.

Aurel is specialized on the mechanical manufacture with CNC or V-Scoring equipments in case of small and medium series, in case of high series with special metal sheet shear. For the last manufacture for high volume, the tiling and the distance between one figure and the other must be assess by our technique office.

Where as traditional PCBs use fiber glass substrates (FR4 is the standard substrate used by PCB fabricators), Aluminum backed PCBs are composed of an aluminum backing, a highly thermally conductive dielectric layer and a standard circuit layer. The circuit layer is essentially a thin PCB that has been bonded to the aluminum backing layer. As such, the circuit layer can be as complex as those mounted on traditional fiber glass backing.

While it is much more common to see single sided designs, it's also possible for an aluminum backed designs to be two sided, with a circuit layer attached through highly thermally conductive dielectric layer on both sides of an aluminum backing. These two sided designs can then be connected by way of plated through holes. Regardless of the configuration the aluminum backing provides an excellent thermal path way to the surrounding environment or any attached heat sink. Once again, improving thermal conduction from power components is the best way to ensure the reliability of your design and aluminum backed PCB offers an excellent solution to this issue.

The solder mask layer of the circuit portion of the board can be made a number of different colors as in traditional PCB designs. That said, in LED designs the solder mask layer is typically white. A white solder mask allows for a higher level of light reflection from the associated LED array and produces a more efficient design. The solder mask is also commonly made black in power designs to better radiate heat.

For furhter information, please feel free to contact us, www.pcbsino.com